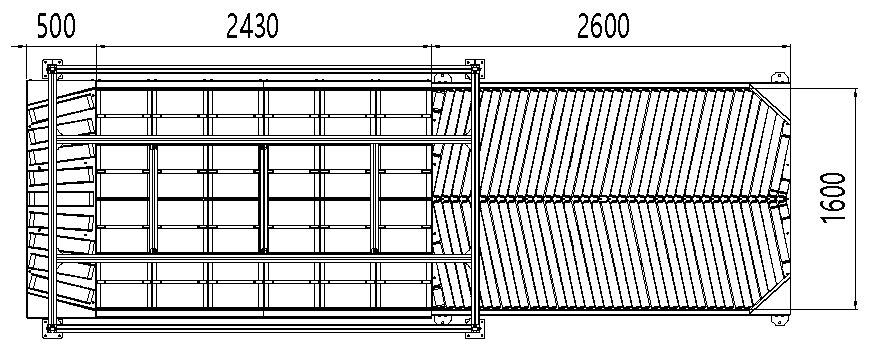

Singulator Separation section size 2000mm(L)X1500mm(W) Single Singular separator size 450mm(L)X150mm(W) Camera depth of field 1000mm Parcel size(LXWXH) Min:150mmX150mmX30mm Max:1500mmX1000mmX1000mm Parcel distance after separation 650±100 Belt width for parcel in-feed end 1000mm or 1200mm Belt speed of output end Above 2m/s Belt width for out-feed end 1200mmSingulador is applied as a front-end/Terminal unloading/ Cross Belt Sorting solution in Dijie’s automatic sortation systems, effectively improving the efficiency of goods sorting work.

Singulator Separation section size 2000mm(L)X1500mm(W) Single Singular separator size 450mm(L)X150mm(W) Camera depth of field 1000mm Parcel size(LXWXH) Min:150mmX150mmX30mm Max:1500mmX1000mmX1000mm Parcel distance after separation 650±100 Belt width for parcel in-feed end 1000mm or 1200mm Belt speed of output end Above 2m/s Belt width for out-feed end 1200mmSingulador is applied as a front-end/Terminal unloading/ Cross Belt Sorting solution in Dijie’s automatic sortation systems, effectively improving the efficiency of goods sorting work.

1. By real-time visual monitoring of the distance between the head and tail of the separated parcels, can get to know the separation quality of the separator that is also called stability of the separation distance. Combined with back-end electrical control, the parcel can be sorted on the back-end sorting line efficiently and successfully. 2. By monitoring the current of all servo motors in the separation section, the potential problems of equipment operation can be found in advance, so as to avoid the loss caused by the subsequent wrong separation.

1. By real-time visual monitoring of the distance between the head and tail of the separated parcels, can get to know the separation quality of the separator that is also called stability of the separation distance. Combined with back-end electrical control, the parcel can be sorted on the back-end sorting line efficiently and successfully. 2. By monitoring the current of all servo motors in the separation section, the potential problems of equipment operation can be found in advance, so as to avoid the loss caused by the subsequent wrong separation.

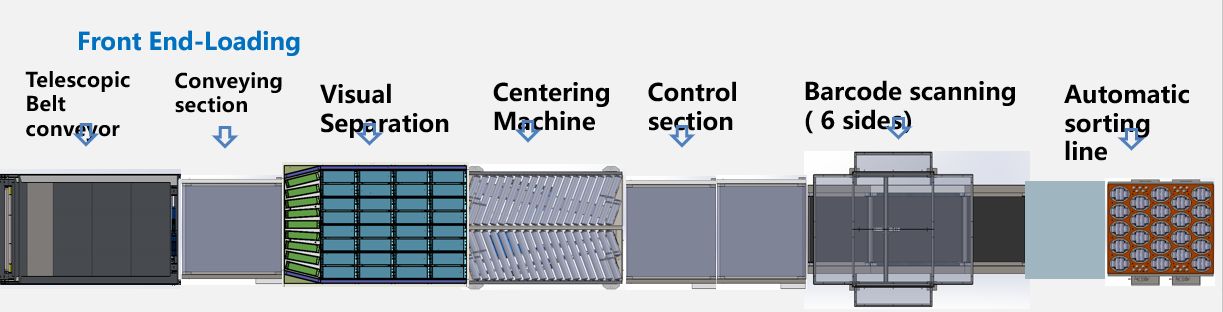

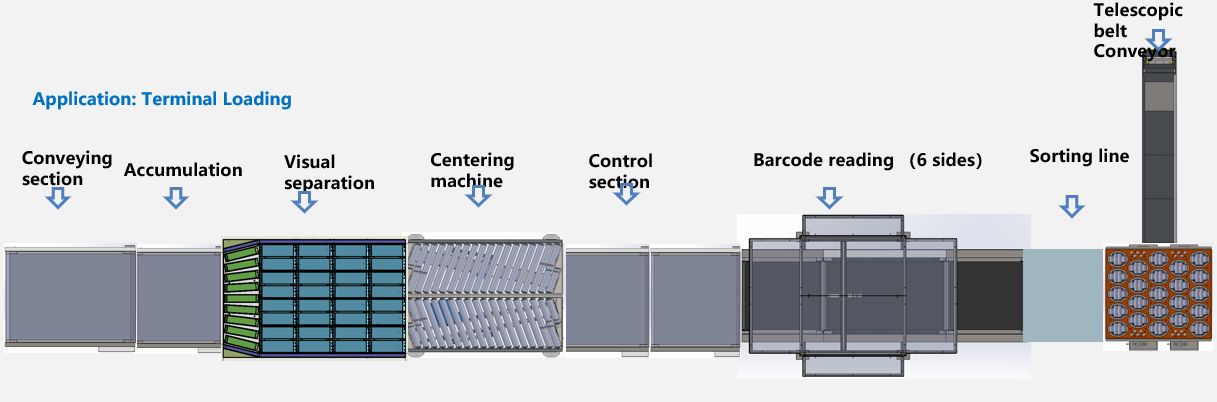

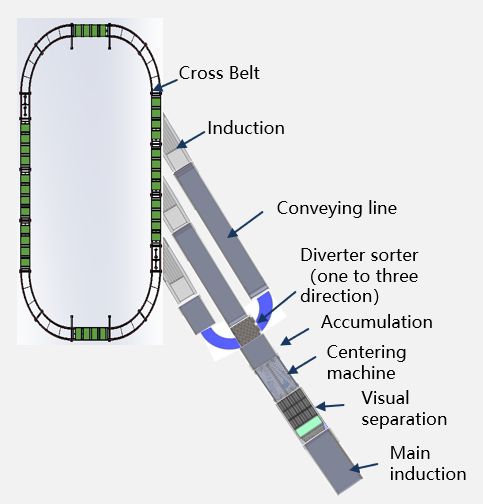

Working Flow : 1. Parcels run into singulator through main line 2. After the camera on the visual separation machine recognizes the parcel position information, it drives a single belt or multiple belts to move through an algorithm, so as to achieve the purpose of separating the parcel in back-and-forth order. 3. After the parcels are separated from front to back, the parcels are arranged in a centered and orderly manner by a centering machine. 4. Parcels enter into the accumulation section, so that the parcels can be transmitted in an orderly manner according to the specified rhythm. 5. According to the control information on the parcel induction platform, the diverter wheel sort parcels into different parcel induction lines. 6. Parcels are automatically sorted through the cross belt on the parcel induction platform

Working Flow : 1. Parcels run into singulator through main line 2. After the camera on the visual separation machine recognizes the parcel position information, it drives a single belt or multiple belts to move through an algorithm, so as to achieve the purpose of separating the parcel in back-and-forth order. 3. After the parcels are separated from front to back, the parcels are arranged in a centered and orderly manner by a centering machine. 4. Parcels enter into the accumulation section, so that the parcels can be transmitted in an orderly manner according to the specified rhythm. 5. According to the control information on the parcel induction platform, the diverter wheel sort parcels into different parcel induction lines. 6. Parcels are automatically sorted through the cross belt on the parcel induction platform