| Item | Parameters |

| Conveying width | 1000mm |

| Conveying speed | 1.5m/s |

| Sorting efficiency | 7200PPH |

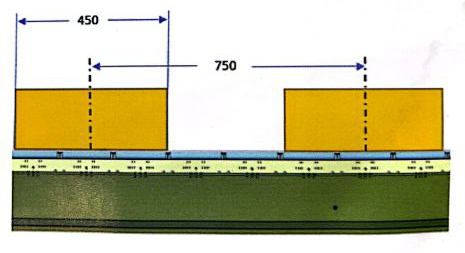

| Max sorting size | 1500X800(LXW) |

| Max sorting weight | 50kg |

| Chute width | 2400-2500mm |

| Min spacing between parcels | 300mm |

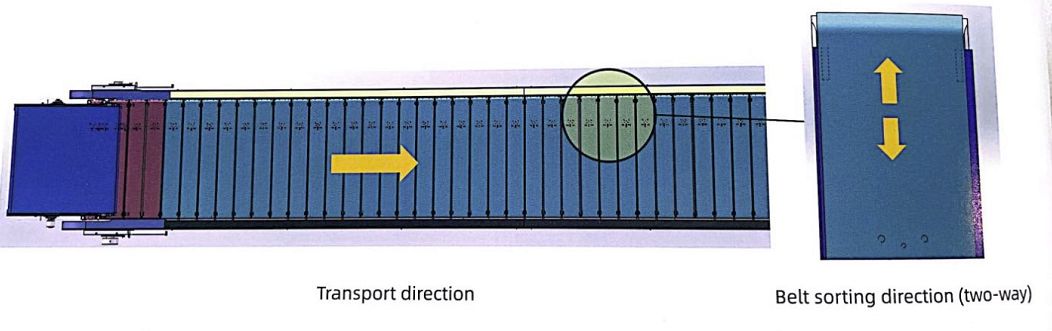

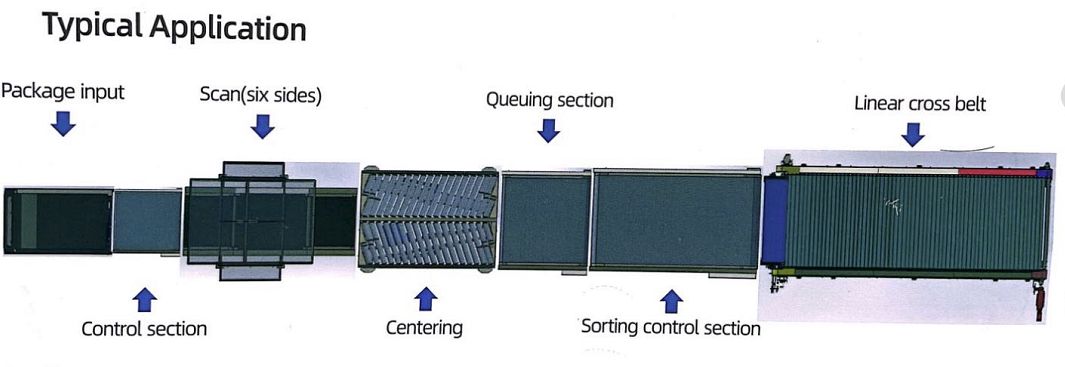

1. In terms of solution floor space, Linear cross belt sorter is much smaller but for small to medium sized logistics and express industries with the storage area limited , the linear cross belt sorter is a good solution to this problem.

2. In addition, linear sorting is more efficient, usually up to 18,000 PPH, with an accuracy rate of 99.99%, and normally tens of thousands PPH efficiency with 1-3 man power can meet this sorting throughput, saving labor cost and making it easy to operate.

3. Linear cross belt sorting system supports automatic code scanning, weighing and measurement, saving sorting and management costs, with stable performance and flexible configuration.

4. Simple operation of loading parcels, configuration can be manually loading and automatic parcel induction. Unloading directly into the telescopic belt machine, to avoid manual handling saving time and effort, and with high efficiency.

5.Linear cross belt sorter can be customized based on the size, the number of intelligent carts, induction table and the size of the chute for automatic parcel dropping. Support inbound and outbound express and e-commerce warehouse sorting and transport.