| Parcel sorting range | Carton, Soft package, Woven bag, Envelope |

| Sorting capacity | 4500pc/h (Based on parcel size length 500mm,linear velocity 2m/s) |

| Sorted Parcel size | Max: 1200mmX800mmX700mm (LXWXH) Min: 120mmX120mmX10mm(LXWXH) |

| Parcel weight | 0.1-50kg |

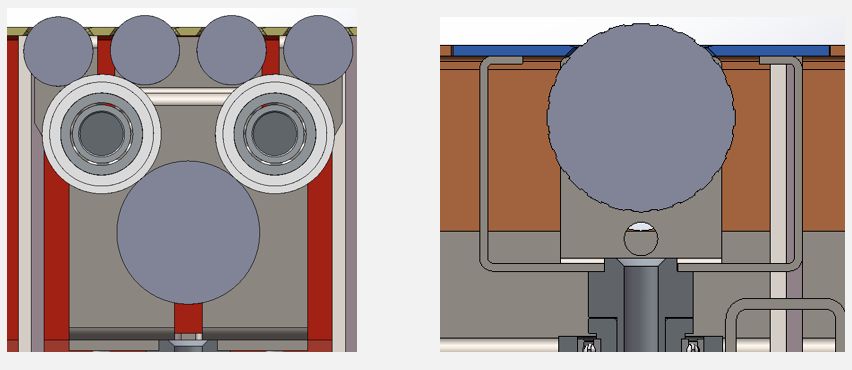

| Wheel | Direct-drive |

| Driving wheel linear velocity | Above 2m/s |

| Two servo motor power | 2X0.75kw=1.5kw |

| Total power for Motorized drive pulley power | 50wX45=2.25kw |

| Total power of diverter sorter | 3.75kw |

| Diverter angle | ±70 |

| Left and right swing period | 0.15s |

| Technical Data | |

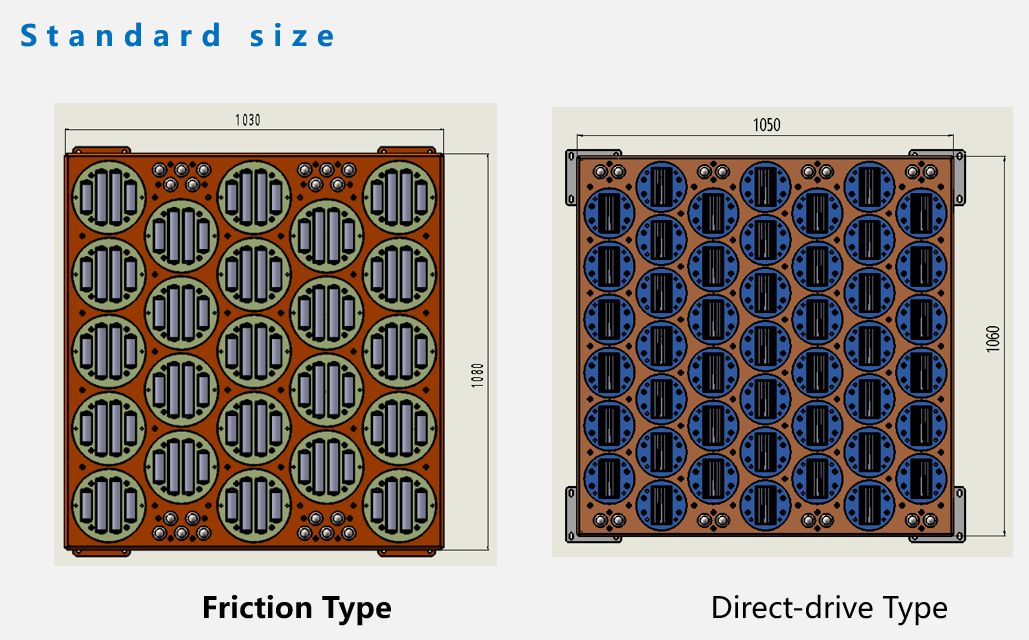

| Roller driving type | Friction drive |

| Conveying width | 1000/1200 can be customized |

| Conveyor wheel sorter line speed | >=2 m/s |

| Total servo motor power (KW) | 0.75X2=1.5KW |

| Electric roller total power (W) | 50X23=1150W=1.15KW |

| Total power (KW) | 2.65 |

| Non-load current(A) | 9~12A |

| Diverting controller angle | +/- 70° |

| Left and right swing period | <=0.25 s |

| Sorted parcel type | Cartons, soft bags, woven bags, letters, special-shaped parts, etc |

| Parcel size | Max:1200(L)X800(W)X700(H) |

| Min:120(L)X120(W)X10(H) | |

| Sorting efficiency (based on 500mm length parcel, line speed at 2m/s) | > 6000 PPH |

| Technical Data Higher efficiency than Friction Type | |

| Roller driving type | Direct-drive |

| Conveying width | 1000/1200 can be customerized |

| Conveyor wheel sorter line speed | >=2 m/s |

| Total servo motor power ((KW) | 0.75X3=2.25KW |

| Electric roller total power (W) | 50X45=2250W=2.25KW |

| Total power (KW) | 4.5 |

| Non-load current(A) | 12~18A |

| Diverting controller angle | +/- 70° |

| Left and right swing period | <=0.25 s |

| Sorted parcel type | Cartons, soft bags, woven bags, letters, special-shaped parts, etc |

| Parcel size | Max:1200(L)X800(W)X700(H) |

| Min :100(L)X100(W)X10(H) | |

| Sorting efficiency (based on 500mm length parcel, line speed at 2m/s | > 6000 PPH |

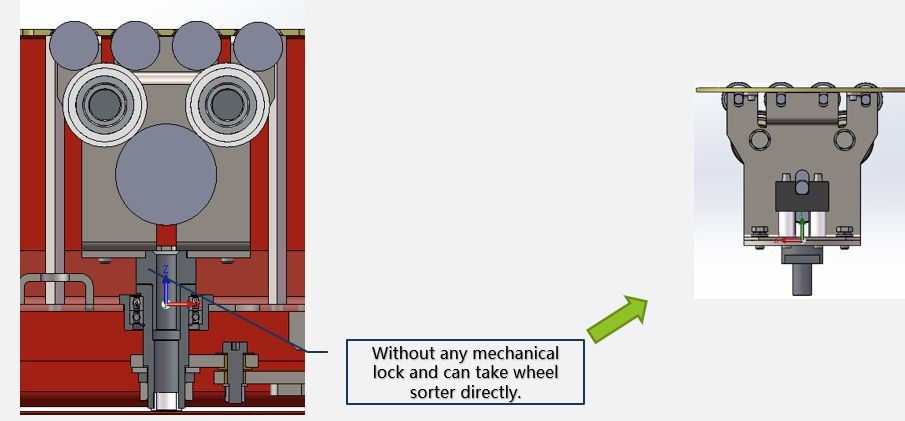

1. Easy disassemble design. Each wheel sorter is independent module, which adopts plug-in-play mode in structure, without mechanical locking such as screws.

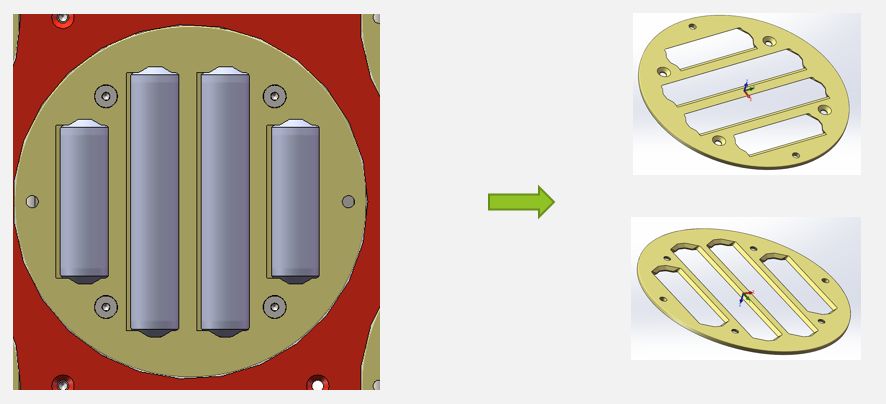

1. Easy disassemble design. Each wheel sorter is independent module, which adopts plug-in-play mode in structure, without mechanical locking such as screws. 2. PVC molding plate which can cover the curved surface space and make the space to the min size.

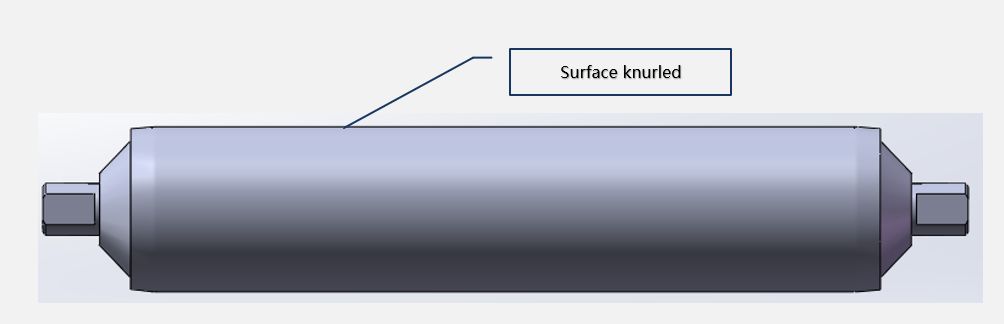

2. PVC molding plate which can cover the curved surface space and make the space to the min size. 3. The surface of the conveying wheel is knurled, which increases the friction force and has a wider application range.

3. The surface of the conveying wheel is knurled, which increases the friction force and has a wider application range.